Industrial Automation Solutions

ANATCO LLC takes full responsibility for the Industrial Control System from conceptual design to after-startup support service and everything in between. We make sure that our customers can keep their focus on their line of business by providing worry-free control system to run their process.

We follow international standards in developing the application software utilizing proven modular software object libraries. Application software testing before shipping is a major stage in our project life-cycle; we take the time to develop the process simulation software that enables our engineers and customers to test-drive their control system prior to delivery assuring the robustness of the application software, shortening the startup and commissioning period, and minimizing operation downtimes.

We assure our customers the peace of mind while we take care of all aspects of the control system including:

- System Architecture Design

- Instrumentation and Control Hardware Selection

- Control Panels Design

- Instruments Procurement

- Control Panels Assembly

- Control Application Software Development & Testing

- Factory Acceptance test

- Instruments Field Installation

- Field Wiring and Containment System

- Commissioning and Startup

- Interface with Other Control Systems and Subsystems

- Integrate the Plant Information with the Enterprise Data Management System

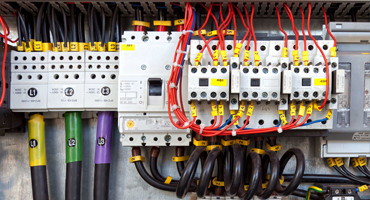

Electrical & Control Panel Assembly

Our team of electrical engineers and assembly technicians are capable of the design and assembly of various types of low voltage panels adhering to the project specifications and the local Utilities rules and regulations complementing our automation solutions and facilitating the integration of the automation and the electrical systems. Our production capabilities including the design and assembly of

- Low Voltage Motor Control Centers (LV MCC)

- Distribution Boards

- Control Panelsn

Third Party Commissioning Management

With extensive industrial domain expertise we provide third party commissioning management services to various industrial and production facilities and help with the project close out. Our commissioning management services including the followings:

- Prepare the Commissioning and Startup Manuals

- Develop the commissioning program

- Coordinate with the vendors and suppliers and other parties involved in the commissioning

- Manage the commissioning activities

- Verify the proper commissioning of the equipment

- Prepare the O&M Manuals

- Administer the operation training

Authorized Supplier for N-Tron Industrial Ethernet Products

ANATCO LLC is the Authorized Supplier for N-Tron Industrial Ethernet products in the United Arab Emirates, Oman, Kuwait, Bahrain, and Qatar.

N-TRON? develops, manufactures, and markets highly reliable industrial network products, designed to solve the most demanding communications requirements in mission critical industrial, data acquisition, Ethernet I/O, and process control applications. Globally recognized as a market leader in the Industrial Ethernet marketplace, N-TRON's products are used throughout the world in a wide variety of applications including wind farms, wastewater treatment plants, nuclear power plants, solar energy, security and surveillance, and process control applications where reliability is an absolute necessity

Authorized Supplier for Acromag Industrial I/O Products

ANATCO LLC is the Factory Authorized Supplier for Acromag's Process and Industrial Automation products in the United Arab Emirates.

Acromag is a multi-million dollar international corporation that combines more than 50 years of process monitoring and control experience with a solid background in high-tech computer design. Established in Michigan, USA in 1957, Acromag built its reputation designing critical measurement instrumentation equipment for the petrochemical and aerospace industries.

Acromag's Process products are compact, high density, high accuracy instruments designed for installations in wide operating temperatures and Class 1, Div 2 areas. They include the following ranges:

- Remote I/O (Ethernet, Modbus and Profibus)

- Isolators & splitters

- Signal conditioning